Intensive Orbital Weld Training

$2,500.00

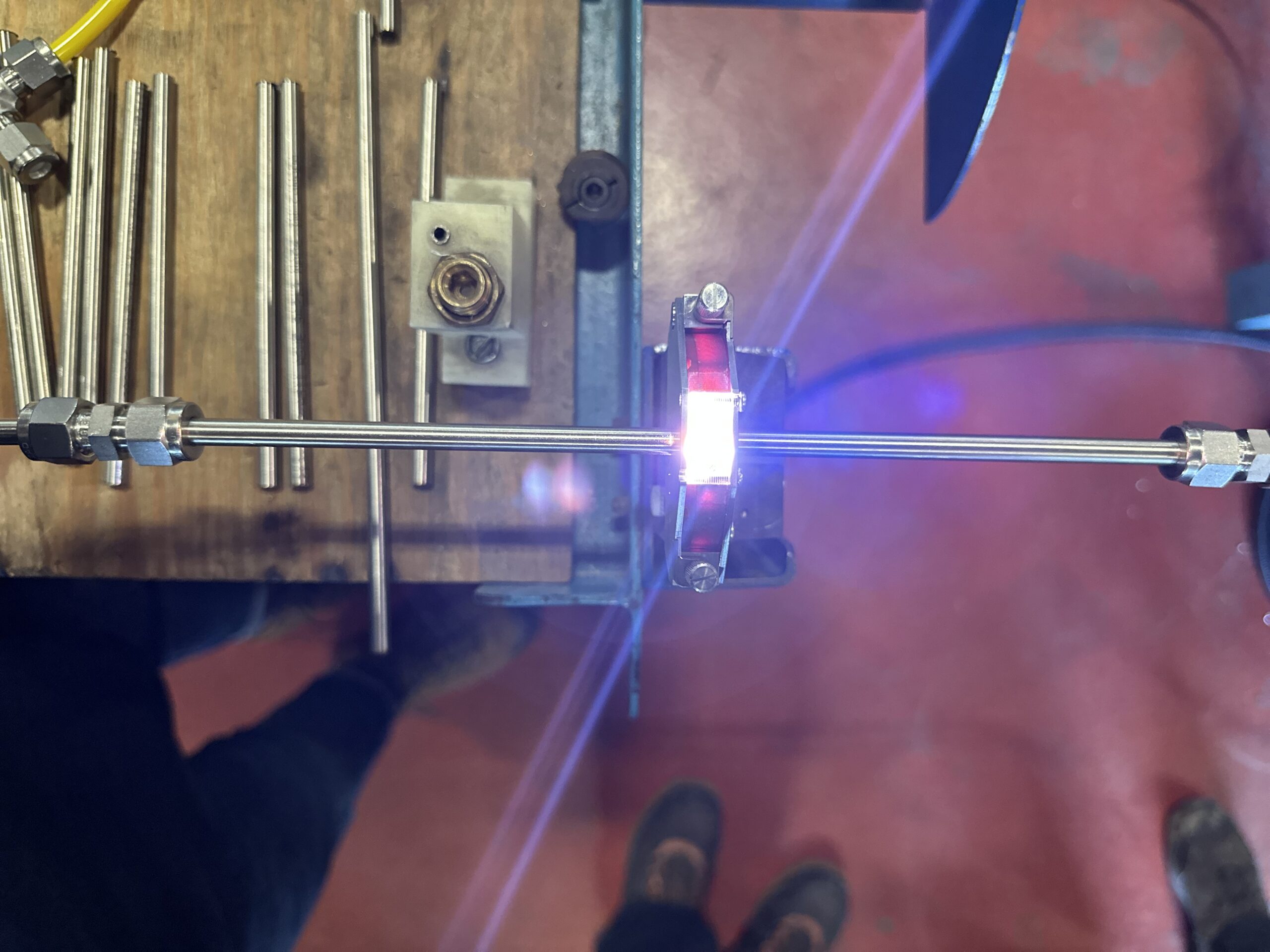

Intensive, Orbital Weld Hands-On Training for Maximum Results Our 5-day/50-hour Orbital Weld course will instruct the entry-level orbital welder and enhance the welding skill knowledge for the experienced orbital welder in the following areas:

- Basic background information

- Basic metallurgy/selection of materials for orbital welding

- Tungsten electrodes life retention, geometry, and proper selection

- Shielding and backing purge gases and procedures (Flow and Pressure)

- Setup and operation of orbital welding equipment

- Preventive maintenance

- Troubleshooting

- Building orbital weld schedules and the benefits of pulse welding

- Industry weld specifications

- Orbital weld evaluation

- A variety of weld procedures through hands-on orbital welding experience on applications from Micro-Fit® fittings to 4 in. diameter tubing

Because of the complexity of the skills required to consistently achieve acceptable orbital welds, it is critical that welders obtain up-to-date and accurate training. The OWETEC approach to learning the theories and skills of GTAW orbital welding includes comprehensive classroom instruction and valuable hands-on training. Our 5-day course provides:

- An understanding of welding principles

- Instructions for setup and operation of the orbital welding system

- Troubleshooting for frequently encountered welding problems.

- An emphasis on operational issues through hands-on experience

We help our customers design weld procedures/programs for socket welds differential wall and ATW fittings, as well as how-to orbital weld large diameter tubing, and help you create welding programs for tacking and welding to show the differences between large diameter and small diameter tubing and demonstrating the purpose of tack welds and Welding of BioPharma fittings.

We explain the features of fixture blocks (i.e., Standard Side Plate v/s Thin Side Plate, Collets (tube & pipe), alignment of side plates, arc gap gage, etc.…), and help create weld program for larger diameter SS tubing. We go in detail on Procedure vs Performance qualifications WPS PQR WOPQ ISO v/s ASME.

All course instructors have earned the qualifications of Certified Weld Inspector (CWI) and Certified Weld Educator (CWE) and have a minimum of five years’ experience in orbital welding instruction. Weld equipment can also be provided for training sessions.

Upon completion of the course, students will each receive a signed certificate of completion, and an ASME Section IX qualification when both exams have been successfully completed.

Intensive, Orbital Weld Hands-On Training for Maximum Results Our 5-day/50-hour Orbital Weld course will instruct the entry-level orbital welder and enhance the welding skill knowledge for the experienced orbital welder in the following areas:

- Basic background information

- Basic metallurgy/selection of materials for orbital welding

- Tungsten electrodes life retention, geometry, and proper selection

- Shielding and backing purge gases and procedures (Flow and Pressure)

- Setup and operation of orbital welding equipment

- Preventive maintenance

- Troubleshooting

- Building orbital weld schedules and the benefits of pulse welding

- Industry weld specifications

- Orbital weld evaluation

- A variety of weld procedures through hands-on orbital welding experience on applications from Micro-Fit® fittings to 4 in. diameter tubing

Because of the complexity of the skills required to consistently achieve acceptable orbital welds, it is critical that welders obtain up-to-date and accurate training. The OWETEC approach to learning the theories and skills of GTAW orbital welding includes comprehensive classroom instruction and valuable hands-on training. Our 5-day course provides:

- An understanding of welding principles

- Instructions for setup and operation of the orbital welding system

- Troubleshooting for frequently encountered welding problems.

- An emphasis on operational issues through hands-on experience

We help our customers design weld procedures/programs for socket welds differential wall and ATW fittings, as well as how-to orbital weld large diameter tubing, and help you create welding programs for tacking and welding to show the differences between large diameter and small diameter tubing and demonstrating the purpose of tack welds and Welding of BioPharma fittings.

We explain the features of fixture blocks (i.e., Standard Side Plate v/s Thin Side Plate, Collets (tube & pipe), alignment of side plates, arc gap gage, etc.…), and help create weld program for larger diameter SS tubing. We go in detail on Procedure vs Performance qualifications WPS PQR WOPQ ISO v/s ASME.

All course instructors have earned the qualifications of Certified Weld Inspector (CWI) and Certified Weld Educator (CWE) and have a minimum of five years’ experience in orbital welding instruction. Weld equipment can also be provided for training sessions.

Upon completion of the course, students will each receive a signed certificate of completion, and an ASME Section IX qualification when both exams have been successfully completed.

Reviews

There are no reviews yet.